Abrasives are used during the repair and painting process to smooth out uneven surfaces or to create a rougher surface texture to ensure good adhesion, or both.

Most abrasives come in discs, strips, sheets and belts. Other shapes are also manufactured for specialist tools, for difficult to reach areas or when only a very small area needs to be sanded.

Automotive abrasives have many names:

- Production Paper

- Wet and Dry Paper

- Sanding Sheets Paper

- Grinding Wheels Paper

- Cutting Wheels Paper

- Wire Wheels Paper

- Grinding Discs Paper

- DA Discs Paper

- Strips of different sizes mainly for use with a Sanding Block Paper

- Sanding Discs Paper

- Mule Skinners Paper

- Scotchbrite Paper

Abrasives have different fixing methods:

- Velcro (or hook and loop) is the most popular. This type of backing needs a backing disc or sanding block with hooks on the surface. The abrasive has a soft material (loop) backing which attaches to the hook very firmly.

- Sticky Back abrasives have a thin adhesive coating on the back and are used with backing pads and sanding blocks which have a vinyl or plastic surface for good adhesion.

- Dry Back abrasives are usually clamped to the power tool or sanding block

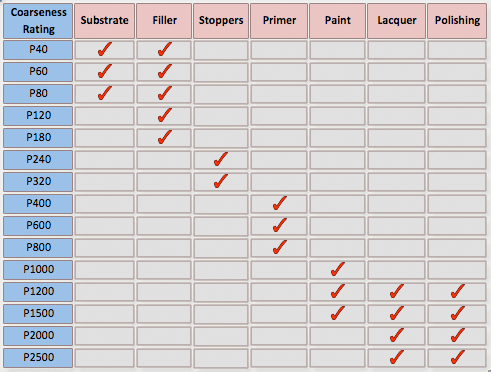

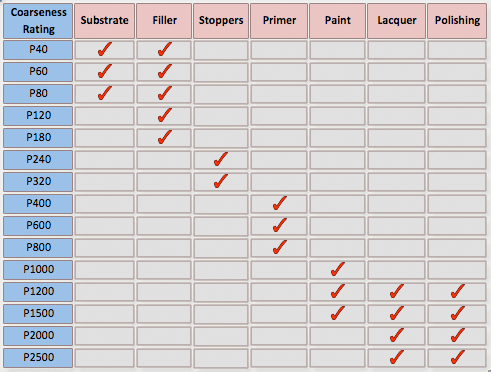

Abrasives have a coarseness rating which is a number defining how coarse or fine the abrasive is – the larger the number, the finer the grit. The coarseness of abrasives used in body repair work ranges from 40 to 2500.

Tips:

- Start with a coarser grit abrasive first. When you are close to the finish you need then move to finer grits as specified in the product’s Technical Data Sheet.

- In some cases the abrasive grit is specified because this is the grit that will promote best adhesion to the next layer. For example, if you only use a coarse grit on filler then the stopper or primer may not bind to the filler properly.

The table below shows which coarseness is generally used on the following surfaces (please refer to the Technical Data Sheet for the correct grit to use):

Other grits are available but not widely used in body repair work.

Most manufacturers of preparation and painting systems will specify the correct abrasive grit to be used in their Technical Data Sheets.

Tips:

Scotchbrite is widely used these days. It is a very fine, webbed, abrasive pad for preparing areas during the painting process that you need to blow or blend in to ensure you have good adhesion. It is also used for sanding awkward areas which do not need any filling or priming.

- Red Scotchbrite (Very Fine) is used for Cellulose and 2K Paints

- Grey Scotchbrite (Ultra Fine) is used for Basecoat Paints and Clearcoat/Lacquer

Tips:

- When sanding by hand always use a flatting block. If you don’t the surface you are sanding will almost always be slightly uneven – you do not want finger ridges in your pride and joy. This unevenness will almost certainly be visible when the final coat is applied and polished.

- Flatting blocks come in various shapes and sizes to suit all surfaces, nooks and crannies.

More Help